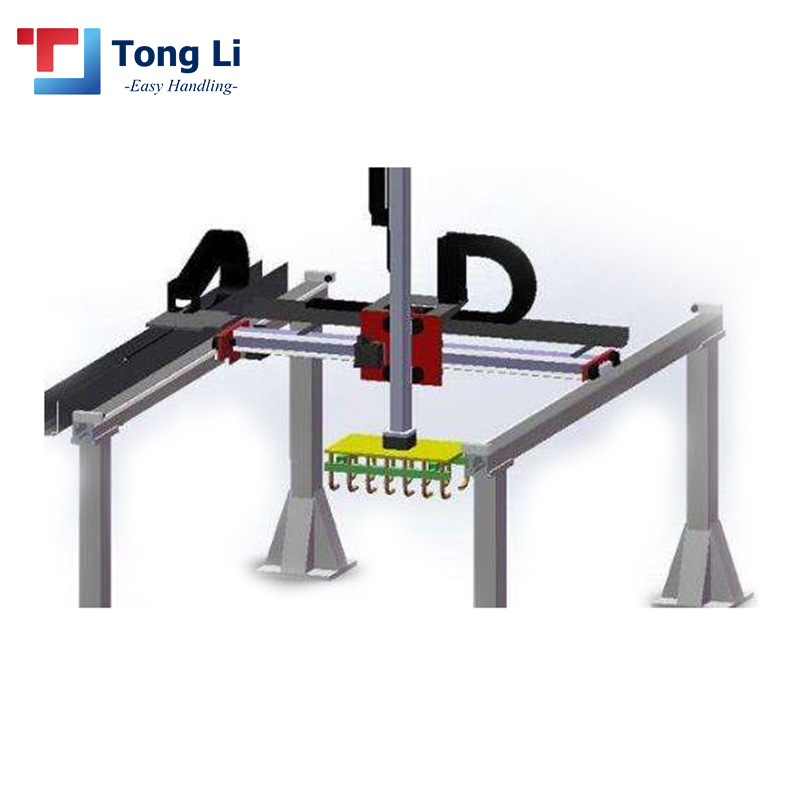

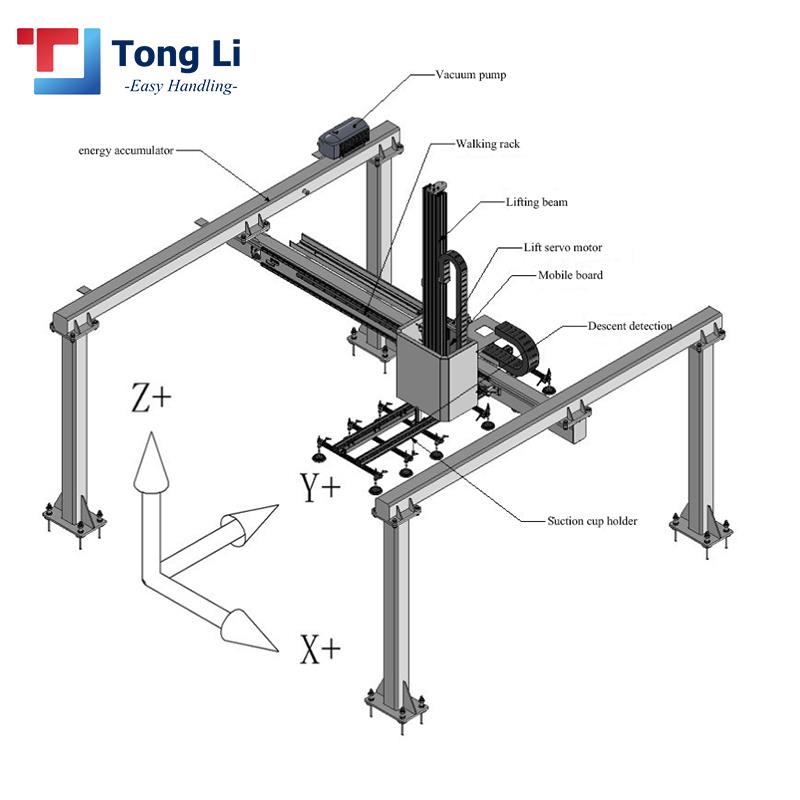

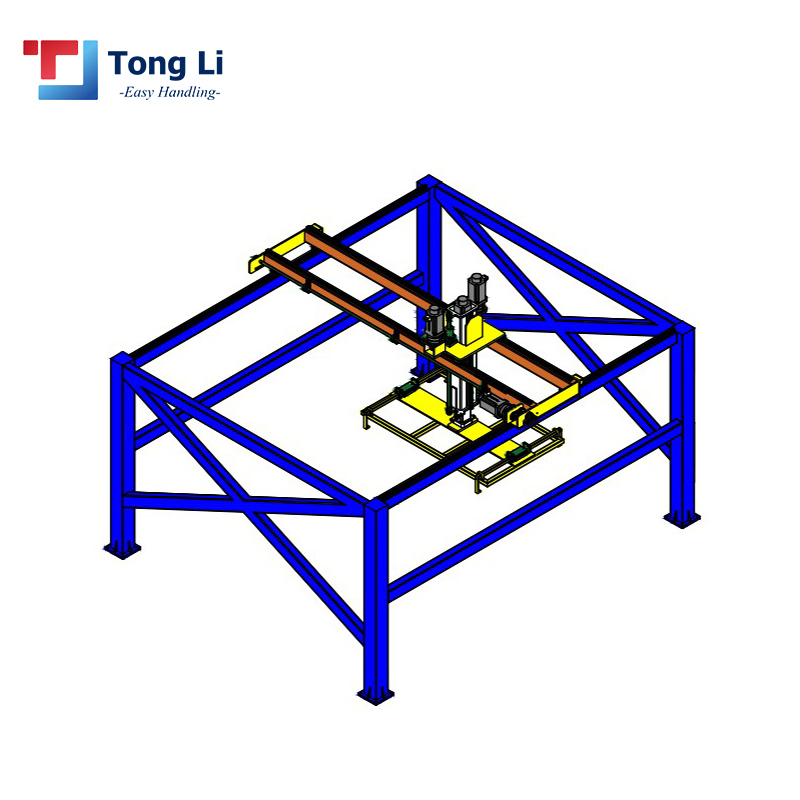

Truss Manipulator

Lub truss manipulator siv cov txheej txheem kev sib xyaw ua ke, uas tsim nyog rau kev thauj khoom thiab tshem tawm cov cuab yeej siv tshuab thiab cov kab ntau lawm, workpiece turnover, workpiece rotation, thiab lwm yam. Nyob rau tib lub sijhawm, nws high-precision clamping thiab positioning tool system muab tus qauv interface rau neeg hlau. kev ua haujlwm tsis siv neeg, thiab rov ua qhov tseeb qhov tseeb kom ntseeg tau siab, ua haujlwm siab thiab sib xws ntawm batch khoom.

Lub truss manipulator yog lub tshuab uas tuaj yeem txiav cov khoom uas tau ntim rau hauv lub thawv (xws li lub thawv, lub hnab ntim, lub thoob, thiab lwm yam) lossis cov khoom ntim thiab tsis ntim khoom.Nws khaws cov khoom ib los ntawm ib qho ntawm ib qho kev txiav txim thiab npaj lawv ntawm lub pallet.Hauv cov txheej txheem, cov khoom tuaj yeem muab tso rau hauv ntau txheej txheej thiab thawb tawm, nws yuav yooj yim mus rau kauj ruam tom ntej ntawm kev ntim khoom thiab xa mus rau lub tsev rau khoom rau kev khaws cia los ntawm forklift.Lub truss manipulator paub txog kev tswj xyuas kev ua haujlwm ntse, uas tuaj yeem txo qis kev siv zog thiab tiv thaiv cov khoom zoo tib lub sijhawm.Nws kuj muaj cov haujlwm hauv qab no: kev tiv thaiv plua plav, tiv thaiv ya raws, tiv thaiv tshav ntuj, hnav tiv thaiv thaum thauj.Yog li ntawd, nws yog dav siv nyob rau hauv ntau lub lag luam xws li tshuaj, dej haus, zaub mov, npias, yas rau cia li stacking ntau yam duab ntawm cov khoom ntim xws li thawv, hnab, kaus poom, npias thawv, fwj thiab hais txog.

1. Auto qhov chaw lag luam

2. Kev lag luam zaub mov

3. Kev lag luam logistics

4. Kev ua haujlwm thiab kev tsim khoom

5. Kev lag luam luam yeeb thiab cawv

6. Kev lag luam ntoo

7. Tshuab cuab yeej ua kev lag luam

| Tsis siv neeg truss manipulator | |||||

| Load (kg) | 20 | 50 | 70 | 100 | 250 |

| Kab ceev | |||||

| X axis (m / s) | 2.3 | 1.8 | 1.6 | 1.6 | 1.5 |

| Y axis (m / s) | 2.3 | 1.8 | 1.6 | 1.6 | 1.5 |

| Z axis (m / s) | 1.6 | 1.3 | 1.3 | 1.1 | 1.1 |

| Scope ntawm kev ua haujlwm | |||||

| X axis (mm) | 1500-45000 | 1500-45000 | 1500-45000 | 1500-45000 | 1500-45000 |

| Y axis (mm) | 1500-8000 Nws | 1500-8000 Nws | 1500-8000 Nws | 1500-8000 Nws | 1500-8000 Nws |

| Z axis (mm) | 500-2000 | 500-2000 | 500-2000 | 500-2000 | 500-2000 |

| Rov ua qhov tseeb qhov tseeb (mm) | ± 0.03 hli | ± 0.03 hli | ± 0.05 hli | ± 0.05 hli | ± 0.07 hli |

| Lubrication system | Concentrated los yog ywj siab lubrication | Concentrated los yog ywj siab lubrication | Concentrated los yog ywj siab lubrication | Concentrated los yog ywj siab lubrication | Concentrated los yog ywj siab lubrication |

| Accelerated ceev (㎡/s) | 3 | 3 | 3 | 2.5 | 2 |